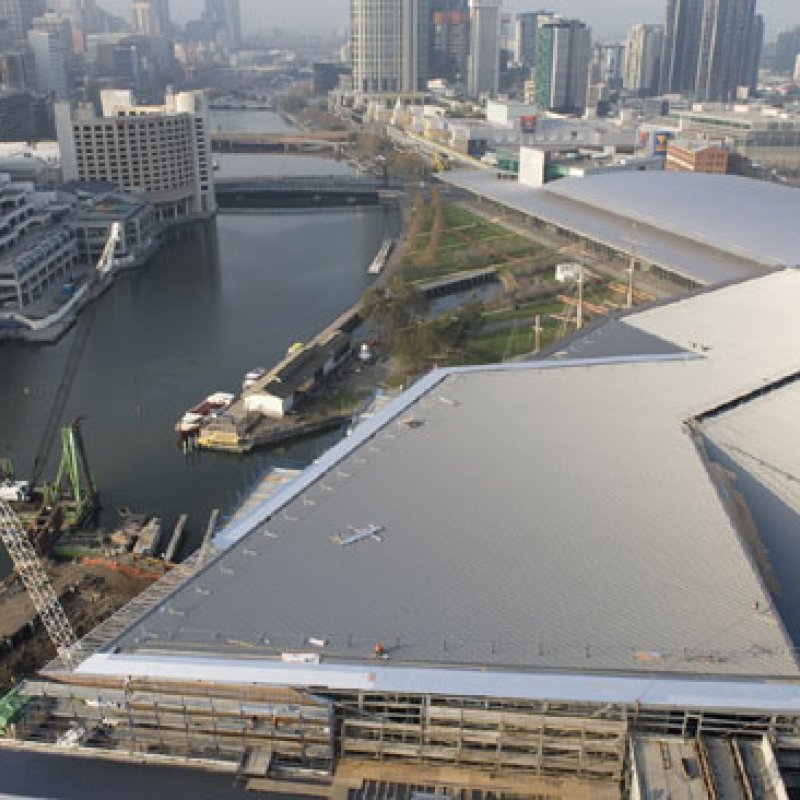

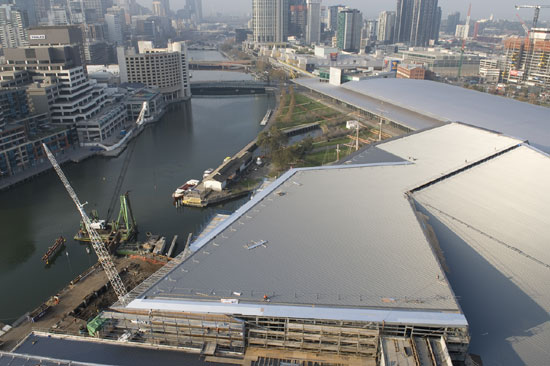

Victorian commercial roofing specialists Aldeck Roofing have continued a lengthy association with Melbourne landmarks by installing the roof for the new Melbourne Convention Centre.

Used in this project

- Products

- LYSAGHT KLIP-LOK 700 HI-STRENGTH®

- Materials

- COLORBOND® steel - Metallic finish

"Over the years we've been involved in projects such as the Vodafone Arena, the Royal Melbourne Showgrounds and the Synchrotron building," Aldeck director Anton Buenemann said.

"We've worked on larger projects, but the Melbourne Convention Centre involved some interesting challenges over almost a year and a half, so this one was special."

The new centre is part of a $1.4 billion development in Melbourne's South Wharf which includes a Hilton Hotel, a lifestyle retail precinct and 60,000 sqm (646,000 sq ft) of shopping space.

Aldeck Roofing is also installing LYSAGHT KLIP-LOK® roofing for the Hilton Hotel.

The new Melbourne Convention Centre has been awarded a 6 Star Green Star environmental rating by the Green Building Council of Australia, the first in the world for a convention centre

It was designed by NHArchitecture and Woods Bagot in association with construction handled by Brookfield Multiplex.

The new centre features an 18-metre-high glass wall facade fronting the Yarra River, a fan-shaped 5,000-seat hall that can be sub-divided into smaller tiered conference venues, a ballroom and 32 meeting rooms of various sizes.

Lysaght provided mobile roll forming services to mill 22,000 square metres of roof cladding on site in sheet lengths up to 75 metres.

"Because of the sheet lengths involved there was no practical alternative to roll forming the cladding on site," Anton Buenemann said.

"This was the first time we had been involved with the process, so naturally there were concerns about everything from occupational health and safety, to quality control and even handling issues.

"All of those matters were settled by the very professional Lysaght crew, who rolled the KLIP-LOK® 700 sheets in COLORBOND® steel in the (Custom) colour Facade® in a Metallic finish, and worked very closely with our installers."

The long roof sheets were roll formed and stacked at ground level to suit the building program, in some cases even before the structural steelwork had been erected.

One of the largest tower cranes in Australia lifted the bundled material as roof frame areas became available and in some cases moved it again to where it was required.

"We worked closely with the Lysaght crew and the success of that teamwork was essential to getting an excellent result," Anton said.

"Because of the triangular shape of the roof, practically every sheet was a different length and we even surveyed the area before the framework was erected to ensure we got the correct sizes.

"We had up to 18 installers walking some of the long sheets into position, but when you are dealing with that much roofing you are getting quick coverage, so it is quite productive."

"We wanted the triangular roof to present large, clean areas unbroken by expansion joints, so on-site roll forming was always the way we wanted to go," Bob Gant of NHArchitecture said.

"Other considerations which led us to the choice of the LYSAGHT® roofing profile and its method of installation were the need for excellent water carrying capacity and the 6 Star Green Star environmental rating we wanted to achieve for the building as a whole.

"Embodied energy, recyclability, transportation and installation are all factored into the rating system and the Melbourne Convention Centre has now achieved that 6 Star status."