Portable Buildings Brisbane is a family-owned and operated business specialising in the manufacture and production of portable and modular buildings. When PBB saw an opportunity to expand its business model into building portable cool rooms, they turned to ASKIN to supply a Kit Room option.

Used in this project

- Products

- ASKIN Interiors EPS-FR

- Materials

- COLORBOND® Intramax® steel

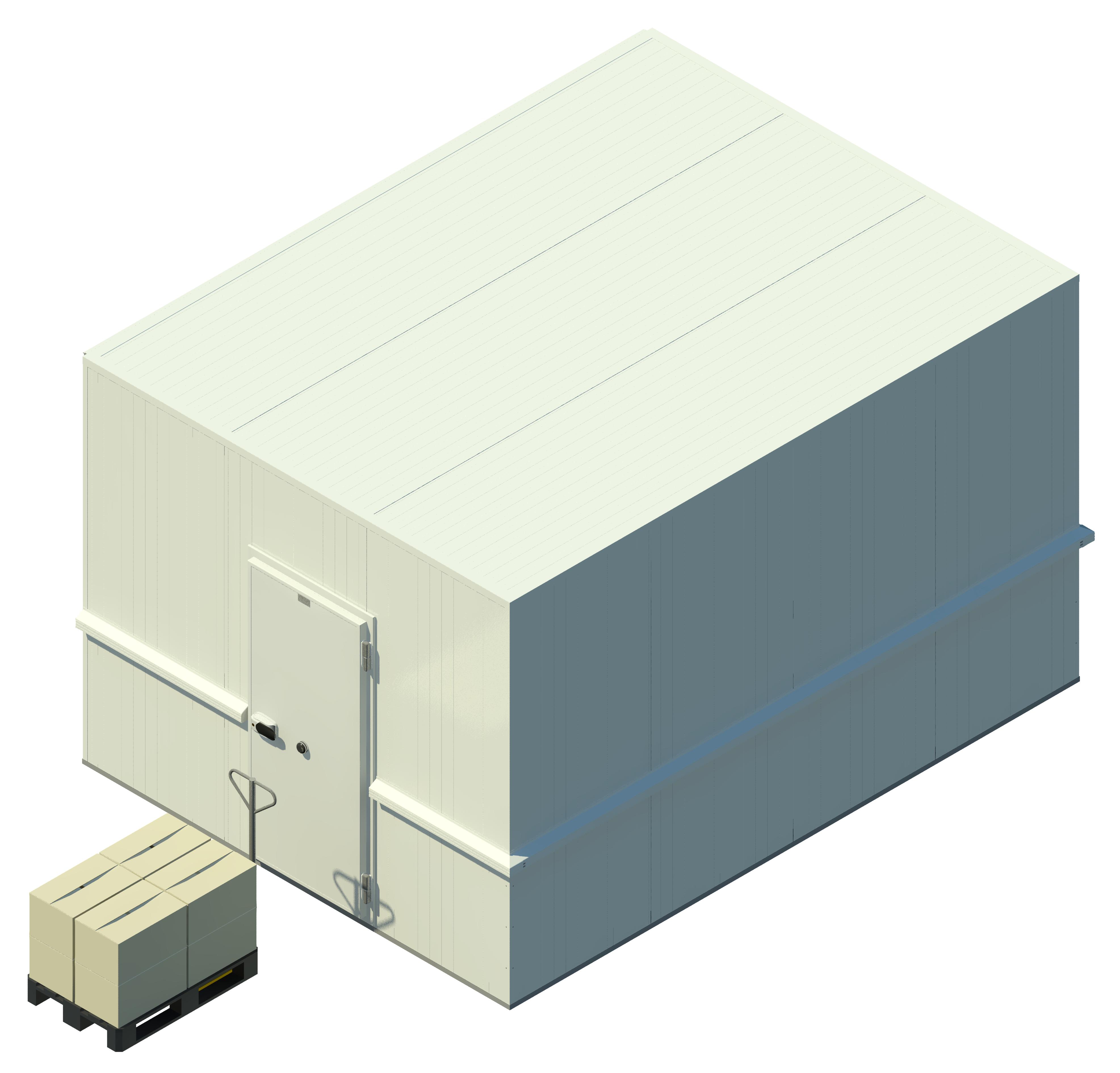

Portable Buildings Brisbane (PBB) has recently seen an opportunity to expand its business model into building portable cool rooms. When they started late in 2018, they were keen to find a reliable panel supplier.

PBB owner Randall Freeman said ASKIN was able to provide accurately cut panels and offered a “kit room” option, meaning PBB didn't have to cut the panel themselves which cost time and money.

“We were looking for a quality panel product when we were introduced to ASKIN,” said Randall. “The ASKIN Kit Room system really was attractive for us, and we’ve been using them ever since.”

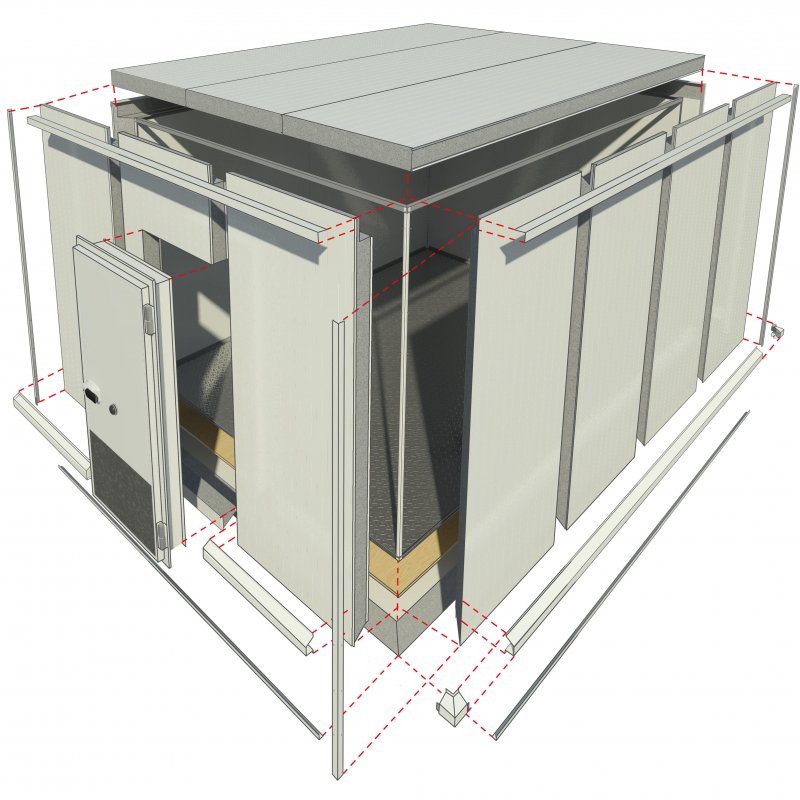

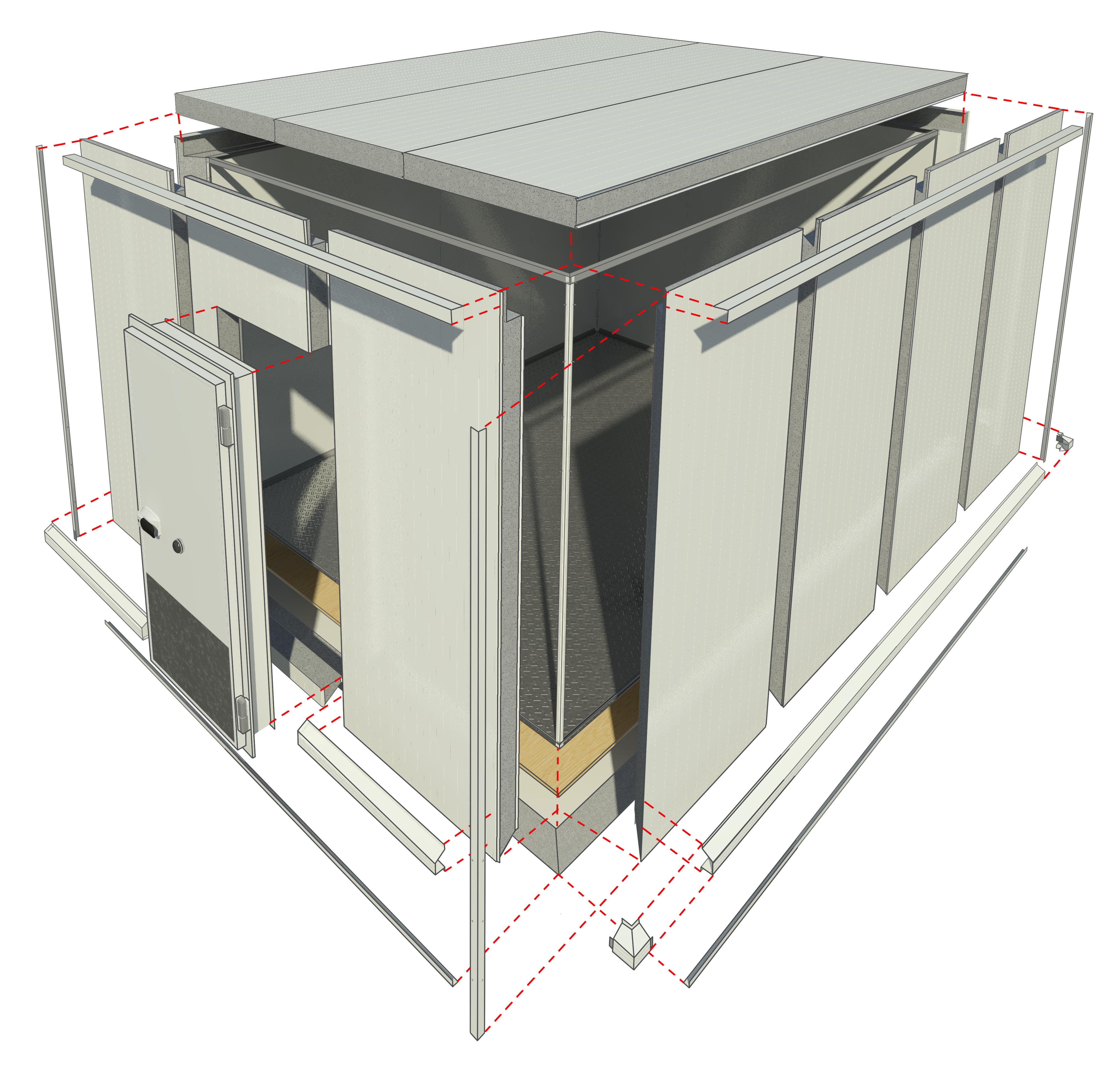

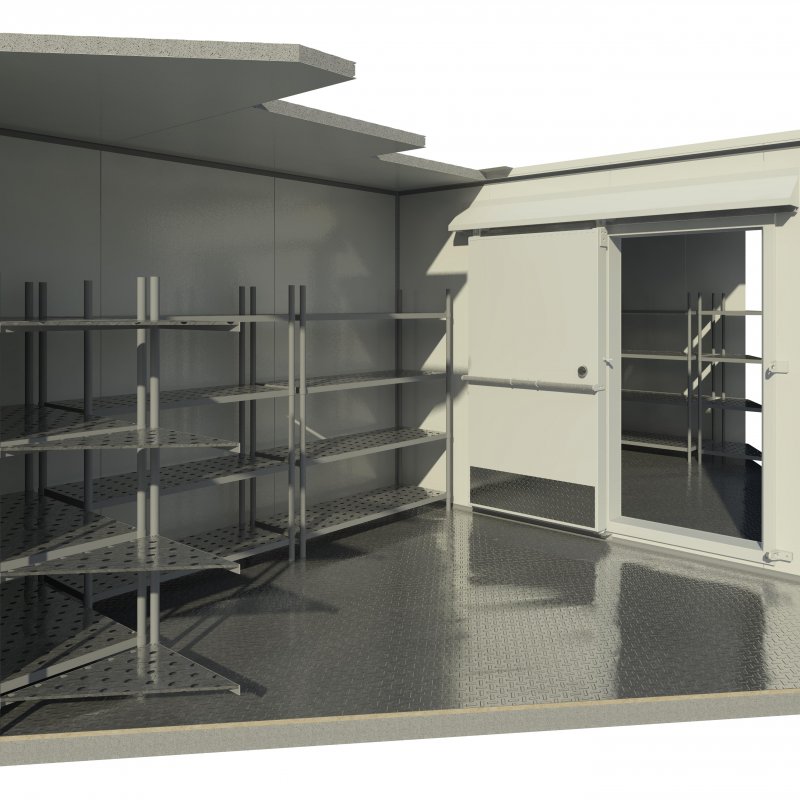

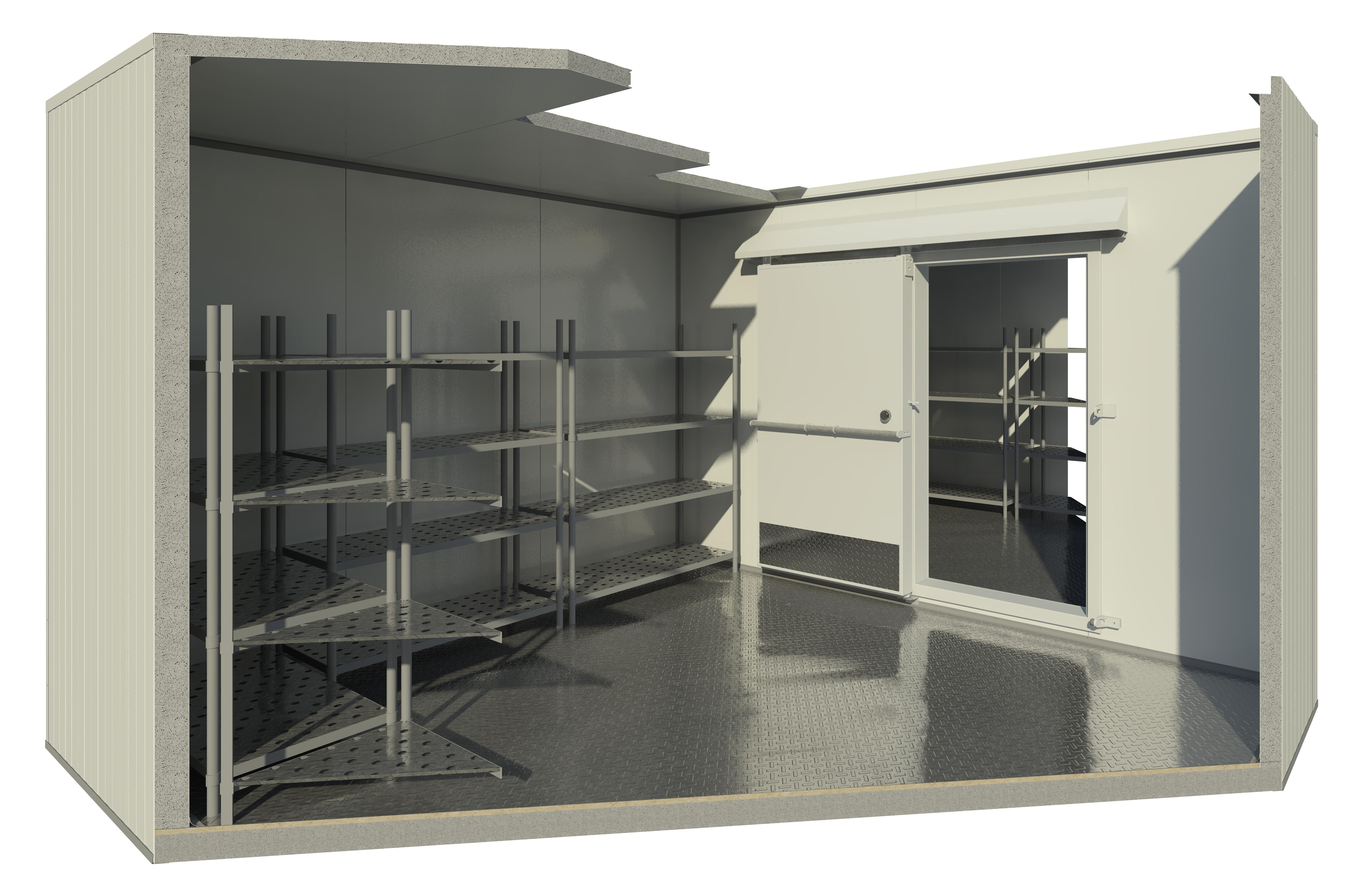

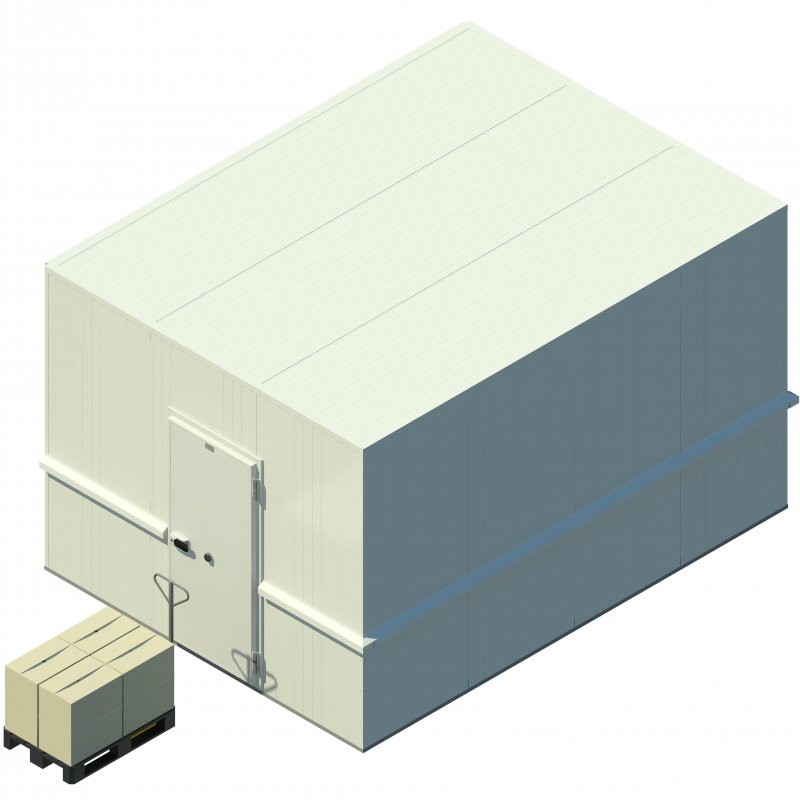

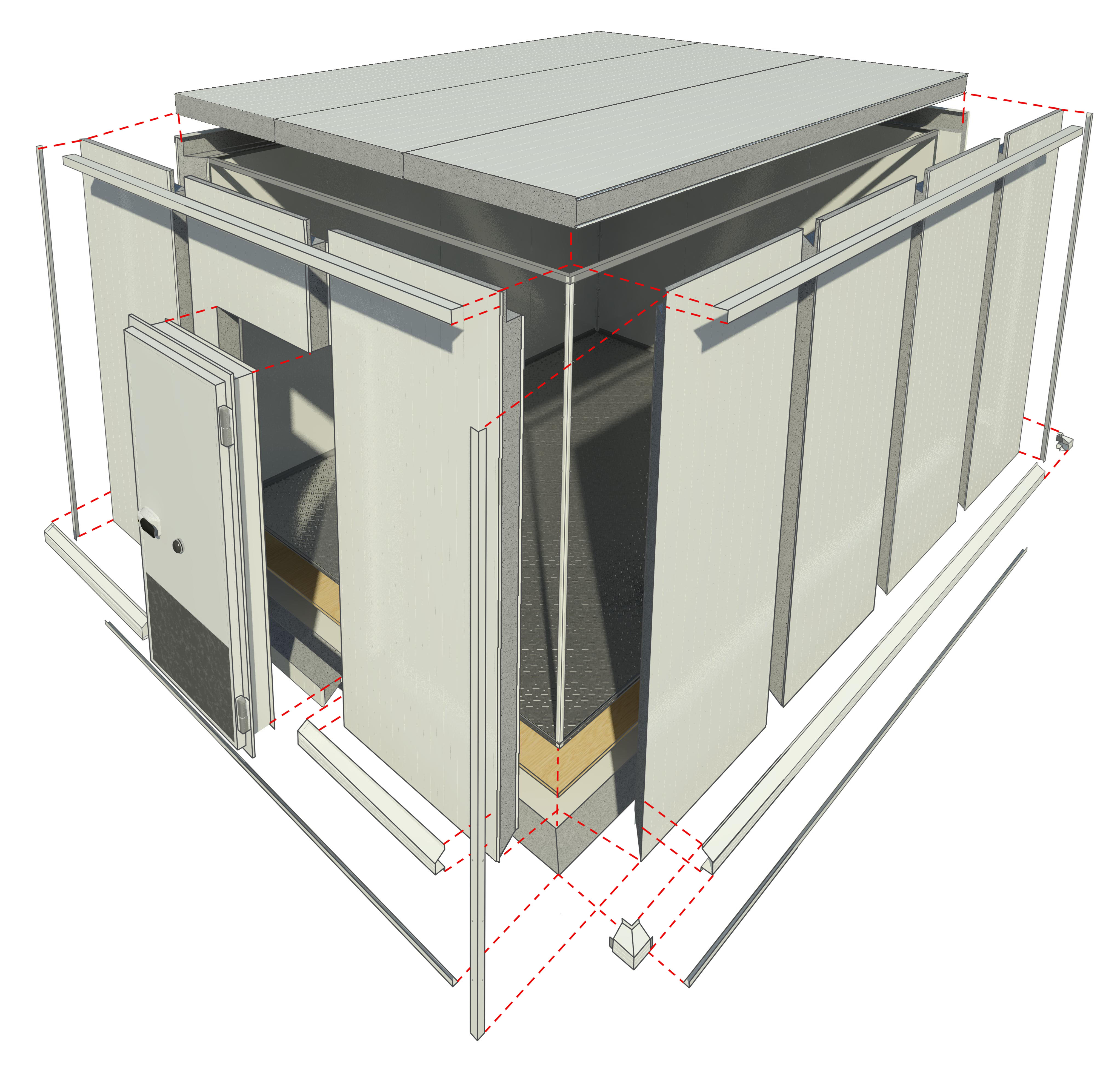

The process is easy when ordering a Kit Room from ASKIN. PBB provide the measurements and the ASKIN design and drafting team provide a detailed drawing ensuring best practice materials and construction methodology. Once approved, PBB is then supplied with an easy to assemble cool room kit which can include a floor if required, walls, ceilings and doors. The kit is also inclusive of fixings, sealants and all consumables required to follow the detailed installation plan provided.

The kits feature EPS-FR ASKIN Panel, with the skins made from COLORBOND® Intramax® steel.

Randall described the Kit Room process as making his part much easier, quicker and more cost-effective to assemble.

“Our experience with ASKIN has always been a good one. We’ve built 11 cool rooms or freezers since we started. The first three we did prior to using ASKIN, and ever since then we have stuck with ASKIN,” he said. “Service and quality are why we use and recommend ASKIN.”